Application of the pole protector for DC motor

Maximum contact capacity thermal protector for DC motor

MOQ :100 piece

Lead Time :7 Days

Product details

Supply Ability

- Supply Ability:50000 piecesWarranty(Year):1 Year

Product Specifications

- Brand name:Baozhu

Product Description

8AM type thermal protection technical specification

1. Product Application

8AM thermal protector can prevent overheating, It is a sudden jump type thermal device.Be used fora variety of motors,Submersible pump,Washing machine,Transformer,Ballast,Locomotive charger,Electrictool,Heating appliance,Home Appliances,Instrument and other equipment.

Auxiliary heating plate of 8AM heat protector with a good matching of the double metal chip,with the function of accurately controlling jump off time over the overload current.When (motor, transformer etc) an overload or blockage current exceeds the set of the thermal protector, The protector can cut off the circuit in 2 ~10 seconds,let object to be protected has thermal overload protection,The product can be reset after manual cutting power.

Note:1,Thermal protectors body size: 27mm×16mm×7.5mm;

2,Can be customized according to customer requirements specifications.

3. Performance

3.1 Contact capacity:AC 115V , 80A

3.2 Rated breaking temperature:80℃~170℃(Per file 5K).

3.3 Tensile test:

Product lead end should be able to withstand greater than or equal to 80N pull,no wire fall off phenomenon

3.4 Insulation Voltage

3.4.1 products should be able to withstand the AC500V between leads when breaking,last 1 min no flashover phenomenon;

3.4.2 Can withstand AC1000V between product leads and insulation sleeve,last 1 min no flashover phenomenon.

3.5 Insulation Resistance

Under normal conditions,the insulation resistance between the lead wire and the insulating paper is above 100M.( The table for the DC500V)

3.6 Contact resistance

The contact resistance of the product should be no more than 50mΩ.

3.7 Protective characteristics

Product pass to 70A current,It’s action time is 2-6S.

3.8 Maximum ambient temperature

Off temperature+20℃,5min Peak temperature:200℃.

3.9 Low temperature test

The product is placed for 96h in the air environment of -40℃.

3.10 Anti vibration test

Thermal protection should be able to withstand the amplitude of 1.5mm,Frequency change 10 ~ 55Hz,Scan change period 3 ~ 5 times /min, In the vibration direction of X, Y, Z continuously vibrate 2h.

3.11 Compression test

3.1 Products should be able to withstand the static pressure of 100N/ 1min.

3.12 Lifetime

Products in the rated voltage, current, power factor for the condition of 0.764, after 1000 times action,The breaking temperature change should be within the initial value of +5;

Note:The following conditions should be met after the 3.8,3.9,3.10,3.11 test:

a.The temperature change should be within the initial value of +7℃;

b.Contact resistance should be below 100mΩ.

4. Other matters:

3.2 The temperature rising rate should be controlled at 1℃/1min;

3.3 Products can not withstand strong impact and stress in the use of the process;

You May Like

- Free Member

- Trade Assurance

Business Type : Manufacturer

Company Location: JIANG SU

Year Established: 21YRS

You May Like

-

Application of the pole protector for DC motor

-

Large current automatic reset thermal protector for Lighting

-

Adjustable temperature control switch motor overload thermal protector for Battery packs

-

Application of the color protector for fractional power motor

-

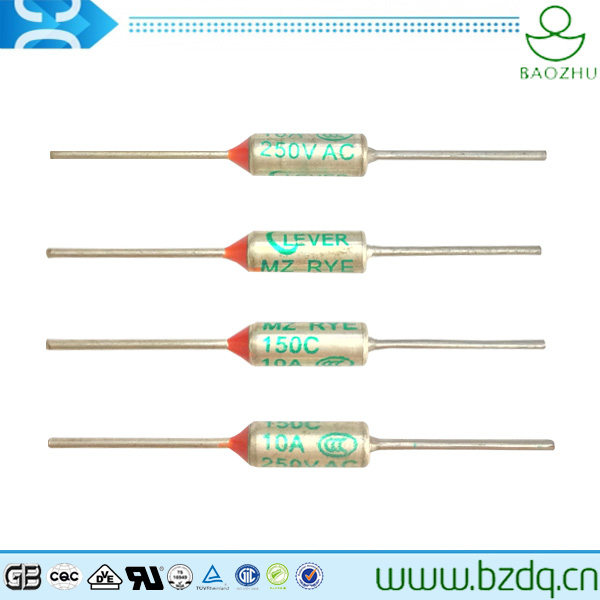

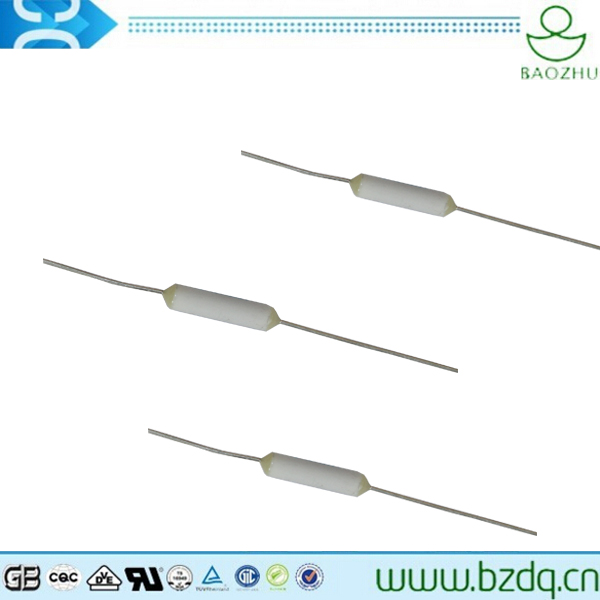

Newest temperature thermal fuse switches for heating appliances

-

Adjustable thermal protector for motor of air conditioner

-

blender thermal protector of positive make and break with snap-action disc

-

thermostats for heating thermal protector

-

motor protector Low resistance thermostat

-

Thermostat for heating Temperature Controller